jan . 29, 2024 16:21 Back to list

How To Make Hydraulic Hoses?

Crimping a hydraulic hose is a crucial aspect of any hose assembly. With several fluids or gases in motion over extended periods of time, the crimp should be just right so that the hose does not damage the application.

FLEXIBLE STAINLESS STEEL METAL HOSE

When using a crimp machine, it is important to know exactly how to use it to ensure consistent, high quality hoses every time. Below is a step-by-step guide to follow when crimping your hydraulic hose.

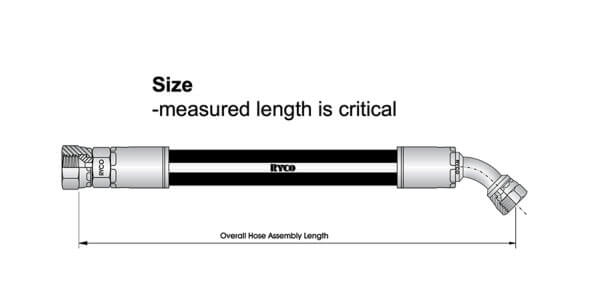

Step 1: Measure and cut the hose

Measure the length of hose that you need and cut it to size with a hose saw.

Step 2: Select fitting series

When selecting a fitting series, consider the working pressure, style, type, orientation, attachment methods and material for its corrosion resistance.

Step 3: Mark insertion depth and push on the hose fittings

Determine insertion depth of the fitting by utilizing a hose insertion depth block. This mark will indicate when the crimp fitting is properly seated on the hose.

Step 4: Load in the correct specifications

Choose the correct crimp diameter for each hose assembly.

Step 5: Select the die

Crimper dies are specifically designed for certain hoses and fittings, so make sure to verify the die is set to the correct specifications.

Step 7: Place the hose in the crimping machine

Push the end of the hose into the crimping machine (typically bottom loading) and through the die so that the hydraulic hose fitting appears above the die. The top of the hose, now concealed inside the fitting, should not be above the die.

Step 8: Crimp the hose

Your hydraulic hose is now ready to begin crimping. Turn on the machine. The cylinder head will slowly move down. As it pushes the collar, the collar compresses the die. Do not touch the machine until the collar is firmly at the bottom of the die. The machine should then stop.

Step 9: Verify the crimp diameter

Check the chalk mark which you made on the hose. If it is no longer at the base of the fitting, it means the hose or the fitting moved during the crimping. However tight it may seem, this is not a good crimp. Otherwise, if the chalk mark is in place, you have successfully crimped the ends of the hydraulic hose. Measure the crimp diameter on a flat surface of the crimped shell and verify the crimp diameter referenced on the decal. Never use hose assemblies with incorrect crimp diameters.

Step 10: Clean hose assembly

Next, you need to remove contaminants within the hose, especially on larger diameter hoses. You can do this by using a hose brush, compressed air system or projectile pellets

Step 11: Cap hose assembly

After you clean the hose again, it is a good idea to cap the assembly on both ends. You can use plastic caps or heat shrink caps.

By following these steps as your guideline, you should achieve a properly assembled hose.

-

Durable 3/8 Rubber Air Hose - GPT-4 Turbo Model

NewsAug.02,2025

-

Premium 3/8 Rubber Air Hose | Durable & High-Pressure

NewsAug.01,2025

-

Durable 3/8" Rubber Air Hose | High Pressure Resistant

NewsJul.31,2025

-

3/8 Rubber Air Hose: Flexible, Durable High-Pressure Air Line

NewsJul.31,2025

-

Durable Rubber Air Hose 3 8 - High Flexibility & Heat Resistance

NewsJul.30,2025

-

Durable Rubber Air Hose 3 8 – Heat & Pressure Resistant, Versatile Use

NewsJul.29,2025