Lug . 02, 2024 14:55 Back to list

What is thermoplastic hydraulic hose

What is thermoplastic hydraulic hose

Thermoplastic hydraulic hose structure

1. inner tube

2. single layer or more layers reinforcement

3. protective outer tube.

thermoplastic hydraulic hose. The inner tube is made from non conductive polyester, high tensile and can burden big pressure. The cover is typically made of materials like polyester, polyethylene, polyurethane, and PVC. It can help protect the internal reinforcement and tube. Extreme-cold applications will be made by materials : polyester elastomer and PTFE.

Thermoplastic hydraulic hose application

Thermoplastic hoses are widely used in medium-to-high pressure hydraulic applications, such as mobile and industrial equipment. Related hoses are often specified for following functions:

handling compressed air and other gases

transporting chemicals

water-cleaning

paint-spray operations

THERMOPLASTIC HOSE SAE 100 R7/ EN 855R7

What is the thermoplastic hydraulic hose advantage

Thermoplastic hydraulic hoses can work in high temperatures that rubber hoses can not stand. And thermoplastic hose has high abrasion resistance to chemicals, saltwater, solvents,etc. It can help maintain overall system cleanliness.

The thermoplastic hose typically has a smooth internal tube that permits highly efficient flow and reduces flow losses. It also tends to offer low expansion even at maximum working pressure.

Compared with rubber hose, the thermoplastic hydraulic hose with a smaller OD in proportion to the ID are important when routing in tight spaces or fitting many hoses in a small available volume. Therefore, more-compact overall dimensions for equal flow.

What's more , the thermoplastic hose’ weight of a given length can be 40% to 60 % less than that of a comparable rubber hydraulic hose. So for specific application requirements,the thermoplastic hydraulic hose is easy routing and quick installation.

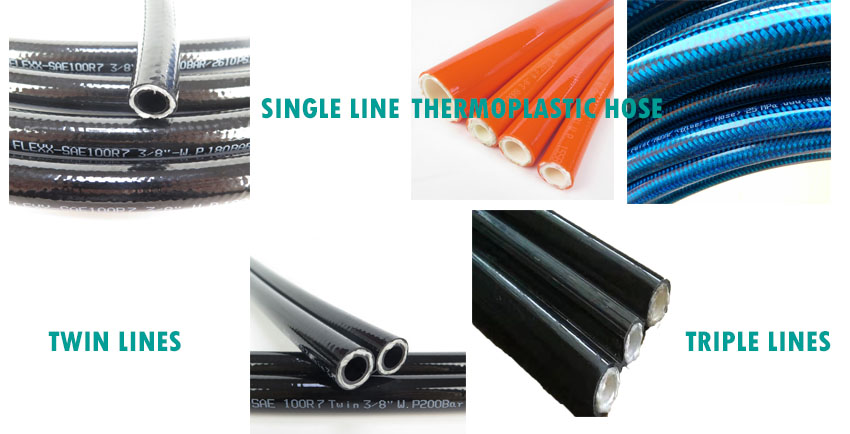

Another advantage is that because thermoplastic hydraulic hose manufacturing has no demand of a mandrel, ID dimensions of 1/16 in. or smaller are possible. This also permits a small bent radius. Thermoplastic hydraulic hose manufacturers can tailor performance characteristics like flexibility and kink resistance, and even customize products for color or shape.

The thermoplastic hose reinforcement layers usually have a braided construction, such as , polyester, aramid fibers, or steel wire. The pressure will have a very large range according to the hose reinforcement. If you want to OEM hose color or pressure, please feel free to contact us. Attractive price but high quality!

-

Extremely High Pressure Hydraulic Hose Durable & High-Performance Solutions

NewsMay.16,2025

-

Marine Hydraulic Hose Flexible R5 Soft Rubber Hoses for High Pressure

NewsMay.16,2025

-

Parker Metal Hose High-Performance Flexible Hydraulic Solutions

NewsMay.16,2025

-

Affordable Flexible Metal Hose Price Reliable Hydraulic Hose Suppliers

NewsMay.15,2025

-

Summit Flexible Hydraulic Hoses - High-Pressure & Corrosion-Resistant

NewsMay.15,2025

-

Hydraulic Hose Guard Durable Flexible Rubber Protection for Heavy Machinery

NewsMay.14,2025