Jan . 29, 2024 15:45 Back to list

How to install cable wrap

Spiral wrap, spiral cable wrap, spiral wire wrap or spiral wrap tubing, whatever you call it, it serves an important purpose.

It’s most often used with a wire harness assembly and to bundle cables, keeping them organised and protected against abrasions. Braided cable sleeving, for example, does this too, but if you need easy access to your cables for any maintenance or repairs, and you don't have a spiral wrap cord organiser then it’s spiral cable wrap and tools that you want.

It’s also cut in a spiral design so that you can route cables at any point from the bundle to a different direction. You can apply spiral wrap to the re-routed bundle that you create too. Its design and construction also enable your cables to flex and even move around, making them ideal for robotic applications. The concept of spiral wrap isn’t just for cables, either.

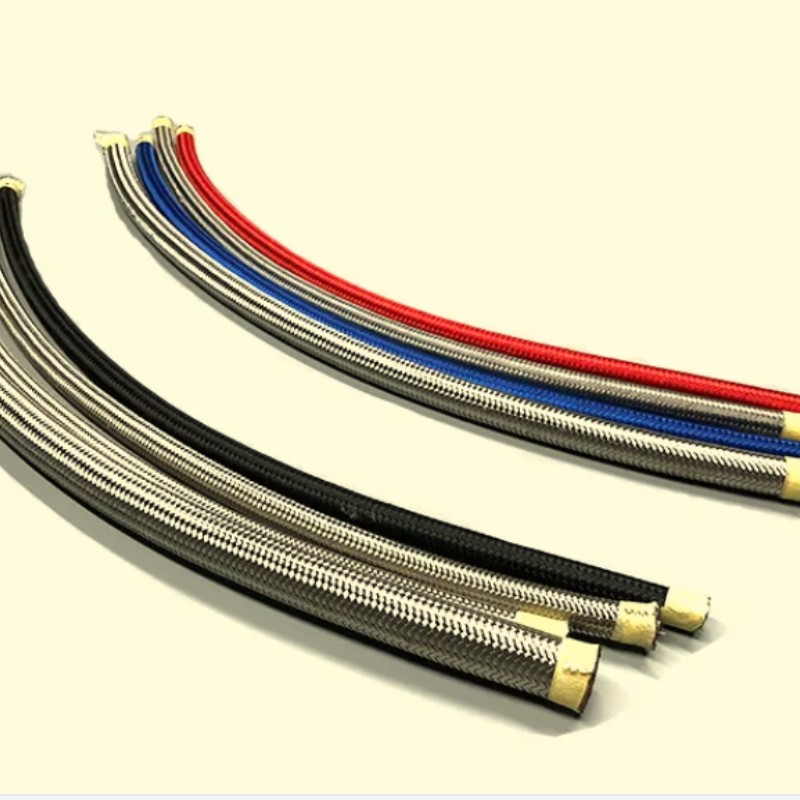

STAINLESS STEEL PTFE HOSE SAE 100R14

Hydraulic spiral wrap protects most types of hydraulic, pneumatic and industrial hose assemblies. If it moves, spiral wrap is the perfect cable management flexible tube. There’s even spiral wrap for heavy-duty uses, such as what the mining industry requires to protect hoses underground.

Spiral wrap is popular across any industry that involves cables and hoses, such as what we find in automotive. For instance, automotive uses spiral wrap to bundle hydraulic hoses for a neat appearance, while also protecting those hoses from punctures and abrasions.

Flexible spiral cable wrap: industries and applications

- Robotics

- Automated manufacturing

- Electronics and control systems

- Utilities

- Electro-mechanical assemblies

- Computer networking systems

- Automotive

- Aeronautical

- Construction

Use polyethylene for general applications

Low cost, polyethylene wrap is the ideal choice if a temperature rating is not needed. It’s incredibly cost effective, and in the colour black, it resists UV rays, so you can use it outdoors. Direct sunlight will not degrade the material, which is why it’s popular with the construction industry. It’s also used as industrial generator parts and in a typical outdoor electrical enclosure and cable junction box.

Otherwise, polyethylene is a general all-purpose material, suitable for standard electrical installations, panel building and the electronics industry.

Generally, polyethylene material has:

| Tensile Strength | 0.20 - 0.40 N/mm² |

| Notched Impact Strength | no break Kj/m² |

| Thermal Coefficient of expansion | 100 - 220 x 10-6 |

| Max Cont Use Temp | 149˚F / 65˚C |

Resistance to chemicals:

| Dilute Acid | Excellent |

| Dilute Alkalis | Excellent |

| Oils and Greases | Moderate (variable) |

| Aliphatic Hydrocarbons | Poor |

| Aromatic Hydrocarbons | Poor |

| Halogenated Hydrocarbons | Poor |

| Alcohols | Excellent |

How to install spiral cable wrap

Your next question is probably how should a spiral wrap be applied? It’s ridiculously easy. No tools are required with cable management spiral wrap.

Step 1. Determine the outside diameter of your cable bundle.

Step 2. Use spiral wrap smaller than your bundle, or it will slip. You have a wide range of spiral cable wrap sizes, so choosing what you need is easy.

Step 3. Cut the length of spiral wrap that you’ll need.

KNOW: How you position the wrap around your cables will dictate your bundle’s flexibility. If you increase the space between the spirals, you can bend cables more sharply. On the flip side, the closer together you space the spirals, then the less flexibility you’ll have, but the trade-off is that you’ll get greater abrasion resistance.

Step 4. Start wrapping the spiral wrap around your bundle of cables and work your way to the other end. (It’s similar to how you’d apply electrical tape.)

Step 5. If you want to route any cables outside of the bundle, do so now.

If later, you want to re-route any cables, simply unwrap the spiral cable wire wrap just enough to remove those cables. You can also reuse it for other applications.

-

Premium 3/8 Rubber Air Hose | Durable & High-Pressure

NewsAug.01,2025

-

Durable 3/8" Rubber Air Hose | High Pressure Resistant

NewsJul.31,2025

-

3/8 Rubber Air Hose: Flexible, Durable High-Pressure Air Line

NewsJul.31,2025

-

Durable Rubber Air Hose 3 8 - High Flexibility & Heat Resistance

NewsJul.30,2025

-

Durable Rubber Air Hose 3 8 – Heat & Pressure Resistant, Versatile Use

NewsJul.29,2025

-

Durable Rubber Air Hose 3 8 – Heat Resistant, Braided & Flexible

NewsJul.29,2025