Jun . 25, 2024 01:49 Back to list

ODM SAE Hydraulic Hose Maintenance and Repair Services

Understanding ODM SAE Hydraulic Hose Service Enhancing Efficiency and Durability in Hydraulic Systems

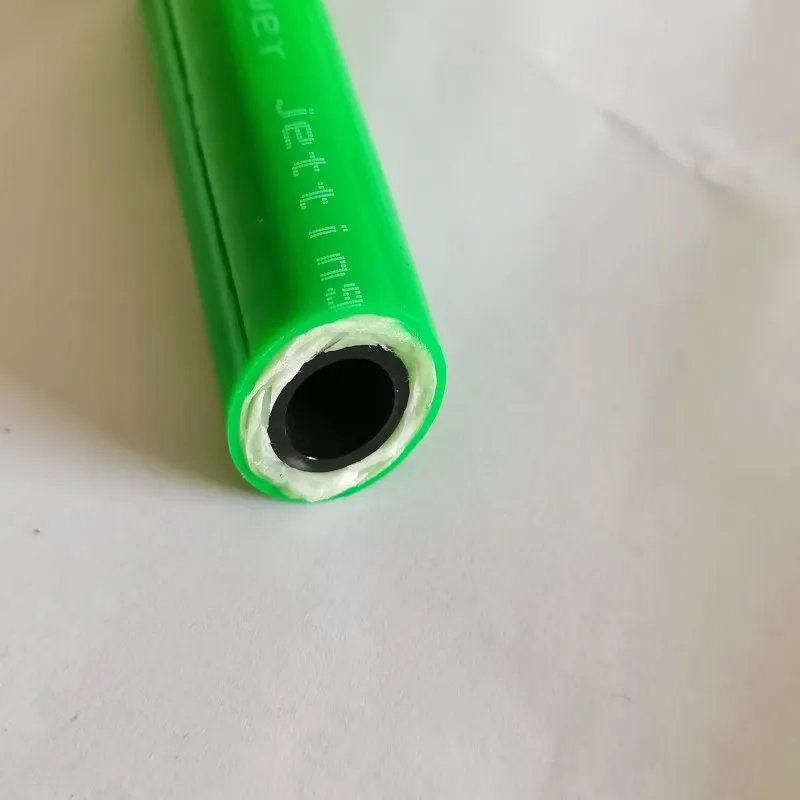

In the realm of hydraulic machinery and equipment, the integrity of hydraulic hoses is paramount to ensure smooth operation, safety, and longevity. ODM (Original Design Manufacturer) SAE (Society of Automotive Engineers) hydraulic hose services play a pivotal role in maintaining these systems by providing hoses that adhere to stringent industry standards, ensuring optimal performance under various demanding conditions. This article delves into the significance of ODM SAE hydraulic hose services, their benefits, and key considerations for selection and maintenance.

**The Significance of SAE Standards in Hydraulic Hoses**

SAE International, a globally recognized organization, sets comprehensive standards for the automotive and aerospace industries, including specifications for hydraulic hoses. These standards encompass material quality, pressure ratings, temperature resistance, and compatibility, among others. By adhering to SAE standards, ODM hydraulic hoses guarantee a level of consistency and reliability that is indispensable in applications ranging from construction equipment to agricultural machinery and industrial plants.

**Key Aspects of ODM SAE Hydraulic Hose Services**

1. **Customization** ODMs offer tailored solutions to meet specific customer requirements. This includes hoses with custom lengths, fittings, and end connections, ensuring a perfect fit for unique system configurations. Customization not only enhances performance but also simplifies installation and maintenance.

2. **Quality Assurance** Quality is the cornerstone of ODM SAE hydraulic hose services. Each hose undergoes rigorous testing to verify its compliance with SAE standards. This includes burst pressure testing, impulse cycle testing for fatigue resistance, and material verification to ensure chemical and heat resistance.

3. **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types

**Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types odm sae hydraulic hose service. This includes low-pressure return lines, medium-pressure service hoses, and high-pressure hydraulic lines, each engineered to excel in their respective roles.

4. **Maintenance and Replacement Services** Beyond manufacturing, ODMs often offer comprehensive hose inspection, maintenance, and replacement services. Regular checks can identify signs of wear or damage before they lead to system failures, thereby minimizing downtime and repair costs. Prompt replacement with genuine SAE-compliant parts ensures continued safety and efficiency.

**Benefits of Utilizing ODM SAE Hydraulic Hose Services**

- **Enhanced System Performance** SAE-compliant hoses optimize fluid flow dynamics, reducing pressure drops and increasing operational efficiency.

- **Safety** The use of high-quality materials and adherence to strict manufacturing standards minimize the risk of leaks and bursts, ensuring a safer working environment.

- **Longevity** Robust construction and material selection extend the lifespan of hoses, reducing the frequency of replacements and overall operating costs.

- **Compatibility and Interchangeability** Adherence to SAE standards ensures that ODM hoses can be seamlessly integrated into existing hydraulic systems, facilitating easy maintenance and upgrades.

**Conclusion**

Opting for ODM SAE hydraulic hose services is a strategic decision that pays dividends in terms of performance, safety, and cost-effectiveness. By leveraging the expertise of ODMs and the assurance of SAE standards, businesses can expect reliable hydraulic systems that stand the test of time and operate at peak efficiency. It is crucial for operators and maintenance teams to understand the importance of using certified hydraulic hoses and to engage in proactive maintenance practices to fully harness the benefits these services offer. In an industry where downtime can equate to significant losses, investing in quality hydraulic hose services is a wise investment towards sustainable productivity and profitability.

odm sae hydraulic hose service. This includes low-pressure return lines, medium-pressure service hoses, and high-pressure hydraulic lines, each engineered to excel in their respective roles.

4. **Maintenance and Replacement Services** Beyond manufacturing, ODMs often offer comprehensive hose inspection, maintenance, and replacement services. Regular checks can identify signs of wear or damage before they lead to system failures, thereby minimizing downtime and repair costs. Prompt replacement with genuine SAE-compliant parts ensures continued safety and efficiency.

**Benefits of Utilizing ODM SAE Hydraulic Hose Services**

- **Enhanced System Performance** SAE-compliant hoses optimize fluid flow dynamics, reducing pressure drops and increasing operational efficiency.

- **Safety** The use of high-quality materials and adherence to strict manufacturing standards minimize the risk of leaks and bursts, ensuring a safer working environment.

- **Longevity** Robust construction and material selection extend the lifespan of hoses, reducing the frequency of replacements and overall operating costs.

- **Compatibility and Interchangeability** Adherence to SAE standards ensures that ODM hoses can be seamlessly integrated into existing hydraulic systems, facilitating easy maintenance and upgrades.

**Conclusion**

Opting for ODM SAE hydraulic hose services is a strategic decision that pays dividends in terms of performance, safety, and cost-effectiveness. By leveraging the expertise of ODMs and the assurance of SAE standards, businesses can expect reliable hydraulic systems that stand the test of time and operate at peak efficiency. It is crucial for operators and maintenance teams to understand the importance of using certified hydraulic hoses and to engage in proactive maintenance practices to fully harness the benefits these services offer. In an industry where downtime can equate to significant losses, investing in quality hydraulic hose services is a wise investment towards sustainable productivity and profitability.

**Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types

**Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types **Extensive Product Range** To cater to diverse applications, ODMs provide a wide array of hydraulic hoses designed for different pressure ranges, temperatures, and media types odm sae hydraulic hose service. This includes low-pressure return lines, medium-pressure service hoses, and high-pressure hydraulic lines, each engineered to excel in their respective roles.

4. **Maintenance and Replacement Services** Beyond manufacturing, ODMs often offer comprehensive hose inspection, maintenance, and replacement services. Regular checks can identify signs of wear or damage before they lead to system failures, thereby minimizing downtime and repair costs. Prompt replacement with genuine SAE-compliant parts ensures continued safety and efficiency.

**Benefits of Utilizing ODM SAE Hydraulic Hose Services**

- **Enhanced System Performance** SAE-compliant hoses optimize fluid flow dynamics, reducing pressure drops and increasing operational efficiency.

- **Safety** The use of high-quality materials and adherence to strict manufacturing standards minimize the risk of leaks and bursts, ensuring a safer working environment.

- **Longevity** Robust construction and material selection extend the lifespan of hoses, reducing the frequency of replacements and overall operating costs.

- **Compatibility and Interchangeability** Adherence to SAE standards ensures that ODM hoses can be seamlessly integrated into existing hydraulic systems, facilitating easy maintenance and upgrades.

**Conclusion**

Opting for ODM SAE hydraulic hose services is a strategic decision that pays dividends in terms of performance, safety, and cost-effectiveness. By leveraging the expertise of ODMs and the assurance of SAE standards, businesses can expect reliable hydraulic systems that stand the test of time and operate at peak efficiency. It is crucial for operators and maintenance teams to understand the importance of using certified hydraulic hoses and to engage in proactive maintenance practices to fully harness the benefits these services offer. In an industry where downtime can equate to significant losses, investing in quality hydraulic hose services is a wise investment towards sustainable productivity and profitability.

odm sae hydraulic hose service. This includes low-pressure return lines, medium-pressure service hoses, and high-pressure hydraulic lines, each engineered to excel in their respective roles.

4. **Maintenance and Replacement Services** Beyond manufacturing, ODMs often offer comprehensive hose inspection, maintenance, and replacement services. Regular checks can identify signs of wear or damage before they lead to system failures, thereby minimizing downtime and repair costs. Prompt replacement with genuine SAE-compliant parts ensures continued safety and efficiency.

**Benefits of Utilizing ODM SAE Hydraulic Hose Services**

- **Enhanced System Performance** SAE-compliant hoses optimize fluid flow dynamics, reducing pressure drops and increasing operational efficiency.

- **Safety** The use of high-quality materials and adherence to strict manufacturing standards minimize the risk of leaks and bursts, ensuring a safer working environment.

- **Longevity** Robust construction and material selection extend the lifespan of hoses, reducing the frequency of replacements and overall operating costs.

- **Compatibility and Interchangeability** Adherence to SAE standards ensures that ODM hoses can be seamlessly integrated into existing hydraulic systems, facilitating easy maintenance and upgrades.

**Conclusion**

Opting for ODM SAE hydraulic hose services is a strategic decision that pays dividends in terms of performance, safety, and cost-effectiveness. By leveraging the expertise of ODMs and the assurance of SAE standards, businesses can expect reliable hydraulic systems that stand the test of time and operate at peak efficiency. It is crucial for operators and maintenance teams to understand the importance of using certified hydraulic hoses and to engage in proactive maintenance practices to fully harness the benefits these services offer. In an industry where downtime can equate to significant losses, investing in quality hydraulic hose services is a wise investment towards sustainable productivity and profitability. Latest news

-

Best Four Steel Wire Spiral Hose Hydraulic R12 – Durable High-Pressure Hose Manufacturer

NewsJul.08,2025

-

High-Quality 1/4 Hydraulic Hose – Soft, Flexible & Durable Rubber Hoses for Industrial Use

NewsJul.08,2025

-

1 1 2 Inch Hydraulic Flexible Hose - Durable, Reliable, High-Pressure Solutions

NewsJul.07,2025

-

High-Quality 1 2 Rubber Hose - Durable, Flexible Hydraulic Solutions

NewsJul.07,2025

-

Discover SAE Hydraulic Hose Types - High Quality & Durable Hoses from Leading Factory Supplier

NewsJul.06,2025

-

High Pressure Wire Hydraulic Rubber Hose Supplier Durable & Reliable 1SN Hose Solutions

NewsJul.06,2025