Jun . 25, 2024 02:01 Back to list

OEM SS304 Braided Metal Hose Quotations

Exploring OEM SS304 Braid Metal Hose Quotes A Comprehensive Guide

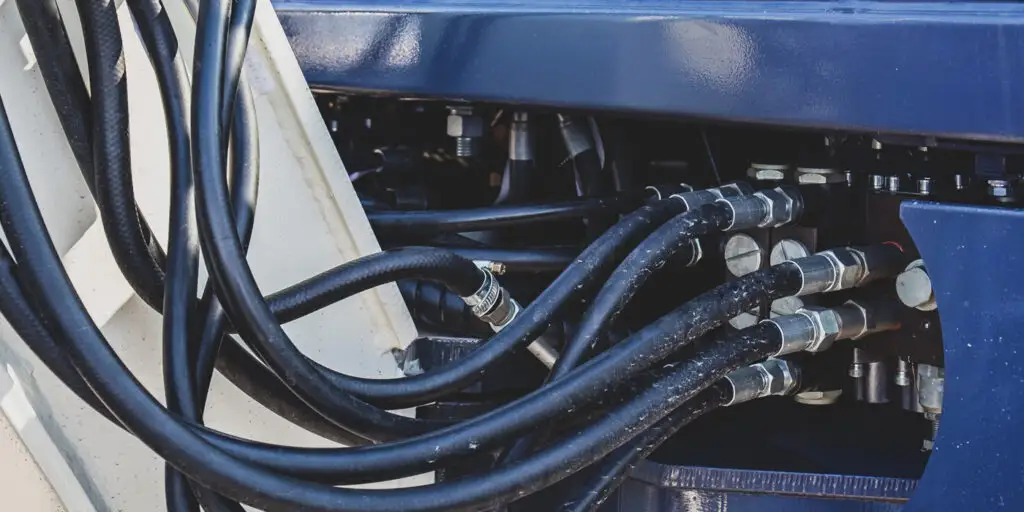

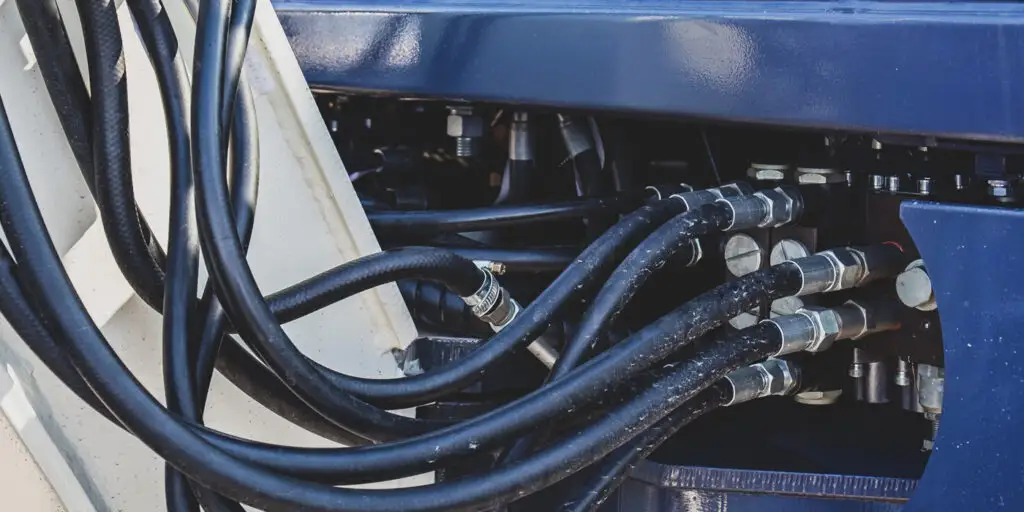

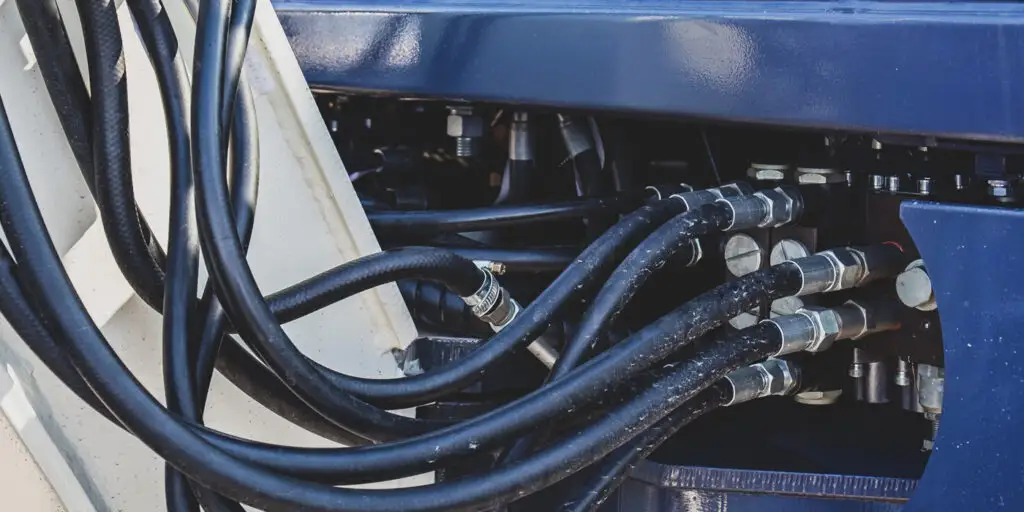

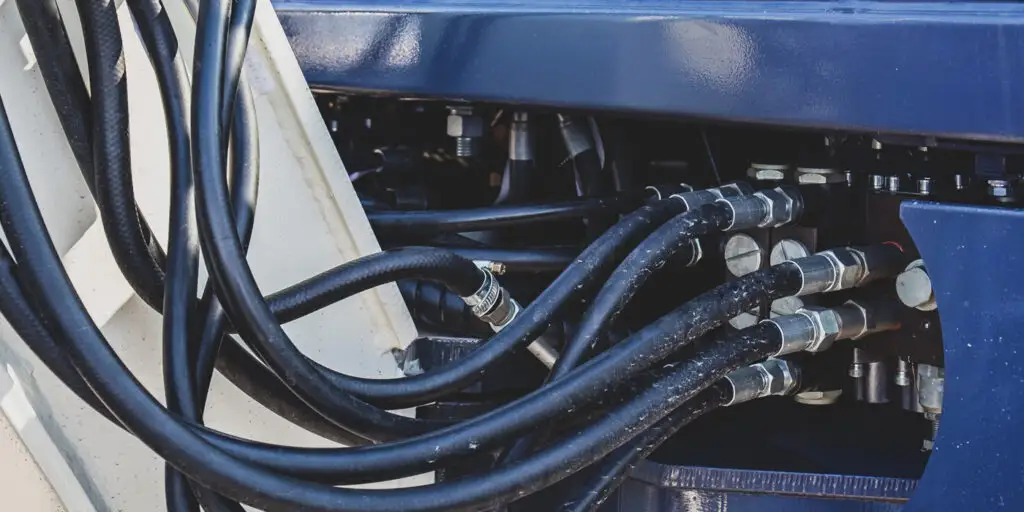

In the realm of industrial applications, where durability and resistance to extreme conditions are paramount, Stainless Steel 304 (SS304) braided metal hoses have established themselves as a reliable and versatile solution. These hoses, known for their ability to withstand high pressure, temperature fluctuations, and corrosive environments, are in high demand across various sectors, including chemical processing, automotive, aerospace, and oil & gas. When it comes to procuring these critical components, obtaining accurate and competitive OEM SS304 braid metal hose quotes becomes a crucial step in the supply chain management process. This article delves into understanding the factors that influence these quotes and how businesses can navigate the quoting process effectively.

Understanding SS304 Braided Metal Hoses

Stainless Steel 304 is a popular choice for metal hoses due to its excellent corrosion resistance, high strength, and durability. The addition of a braiding layer, typically also made from SS304, significantly enhances the hose's pressure capacity and provides protection against external damage, making it suitable for conveying fluids under demanding conditions.

Factors Affecting Quotations

1. Hose Specifications

The dimensions of the hose, including its length, inner diameter (ID), and outer diameter (OD), directly impact the material required and thus the cost. Additionally, the operating pressure and temperature requirements dictate the thickness of the wall and the complexity of the braiding pattern, influencing the quote.

2. Quantity and Customization

OEMs often offer volume discounts, so the quantity of hoses required plays a significant role in determining the per-unit cost. Customizations such as end fittings, special coatings, or unique lengths may increase the price due to additional manufacturing processes involved.

3. Material Costs

Fluctuations in stainless steel prices on the global market can affect the overall quote. Suppliers who can secure materials at competitive rates are more likely to provide attractive pricing.

4. Manufacturing Capabilities

The manufacturer's production capacity, technology, and efficiency influence pricing. Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer

Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer oem ss304 braid metal hose quotes.

5. Lead Time

Urgent orders requiring expedited manufacturing and shipping can incur additional fees. Understanding lead times and planning accordingly can help manage costs.

Navigating the Quoting Process

Research and Selection

Begin by identifying reputable OEMs with expertise in SS304 braided metal hoses. Review their capabilities, quality certifications, and client testimonials to shortlist potential suppliers.

Detailed Specification Submission

Provide the OEM with a comprehensive list of your requirements, including hose specifications, quantity, any customizations, and your expected delivery timeline. Clear communication ensures accurate and comparable quotes.

Request for Quote (RFQ)

Issue a formal RFQ to your shortlisted suppliers, outlining all necessary details. This structured approach encourages transparency and consistency in the quotations received.

Evaluation and Negotiation

Evaluate each quote based on not just the price but also considering lead time, quality assurance, and post-sale services. Engage in negotiations if needed, leveraging volume purchases or discussing areas where costs might be reduced without compromising quality.

Finalizing the Deal

Once you've chosen the most favorable quote, confirm the order details, payment terms, and warranty provisions. Establishing a clear contract helps prevent misunderstandings down the line.

Conclusion

Securing competitive OEM SS304 braid metal hose quotes demands a thorough understanding of your specific needs and a strategic approach to supplier engagement. By carefully considering all influencing factors and following a structured quotation process, businesses can ensure they obtain the best value for their investment while maintaining the high standards essential for their operations. Remember, the right partnership with an OEM can lead to long-term cost savings, enhanced product performance, and a solid foundation for your business's growth.

oem ss304 braid metal hose quotes.

5. Lead Time

Urgent orders requiring expedited manufacturing and shipping can incur additional fees. Understanding lead times and planning accordingly can help manage costs.

Navigating the Quoting Process

Research and Selection

Begin by identifying reputable OEMs with expertise in SS304 braided metal hoses. Review their capabilities, quality certifications, and client testimonials to shortlist potential suppliers.

Detailed Specification Submission

Provide the OEM with a comprehensive list of your requirements, including hose specifications, quantity, any customizations, and your expected delivery timeline. Clear communication ensures accurate and comparable quotes.

Request for Quote (RFQ)

Issue a formal RFQ to your shortlisted suppliers, outlining all necessary details. This structured approach encourages transparency and consistency in the quotations received.

Evaluation and Negotiation

Evaluate each quote based on not just the price but also considering lead time, quality assurance, and post-sale services. Engage in negotiations if needed, leveraging volume purchases or discussing areas where costs might be reduced without compromising quality.

Finalizing the Deal

Once you've chosen the most favorable quote, confirm the order details, payment terms, and warranty provisions. Establishing a clear contract helps prevent misunderstandings down the line.

Conclusion

Securing competitive OEM SS304 braid metal hose quotes demands a thorough understanding of your specific needs and a strategic approach to supplier engagement. By carefully considering all influencing factors and following a structured quotation process, businesses can ensure they obtain the best value for their investment while maintaining the high standards essential for their operations. Remember, the right partnership with an OEM can lead to long-term cost savings, enhanced product performance, and a solid foundation for your business's growth.

Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer

Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer Advanced machinery can reduce waste and speed up production, potentially translating to cost savings passed onto the customer oem ss304 braid metal hose quotes.

5. Lead Time

Urgent orders requiring expedited manufacturing and shipping can incur additional fees. Understanding lead times and planning accordingly can help manage costs.

Navigating the Quoting Process

Research and Selection

Begin by identifying reputable OEMs with expertise in SS304 braided metal hoses. Review their capabilities, quality certifications, and client testimonials to shortlist potential suppliers.

Detailed Specification Submission

Provide the OEM with a comprehensive list of your requirements, including hose specifications, quantity, any customizations, and your expected delivery timeline. Clear communication ensures accurate and comparable quotes.

Request for Quote (RFQ)

Issue a formal RFQ to your shortlisted suppliers, outlining all necessary details. This structured approach encourages transparency and consistency in the quotations received.

Evaluation and Negotiation

Evaluate each quote based on not just the price but also considering lead time, quality assurance, and post-sale services. Engage in negotiations if needed, leveraging volume purchases or discussing areas where costs might be reduced without compromising quality.

Finalizing the Deal

Once you've chosen the most favorable quote, confirm the order details, payment terms, and warranty provisions. Establishing a clear contract helps prevent misunderstandings down the line.

Conclusion

Securing competitive OEM SS304 braid metal hose quotes demands a thorough understanding of your specific needs and a strategic approach to supplier engagement. By carefully considering all influencing factors and following a structured quotation process, businesses can ensure they obtain the best value for their investment while maintaining the high standards essential for their operations. Remember, the right partnership with an OEM can lead to long-term cost savings, enhanced product performance, and a solid foundation for your business's growth.

oem ss304 braid metal hose quotes.

5. Lead Time

Urgent orders requiring expedited manufacturing and shipping can incur additional fees. Understanding lead times and planning accordingly can help manage costs.

Navigating the Quoting Process

Research and Selection

Begin by identifying reputable OEMs with expertise in SS304 braided metal hoses. Review their capabilities, quality certifications, and client testimonials to shortlist potential suppliers.

Detailed Specification Submission

Provide the OEM with a comprehensive list of your requirements, including hose specifications, quantity, any customizations, and your expected delivery timeline. Clear communication ensures accurate and comparable quotes.

Request for Quote (RFQ)

Issue a formal RFQ to your shortlisted suppliers, outlining all necessary details. This structured approach encourages transparency and consistency in the quotations received.

Evaluation and Negotiation

Evaluate each quote based on not just the price but also considering lead time, quality assurance, and post-sale services. Engage in negotiations if needed, leveraging volume purchases or discussing areas where costs might be reduced without compromising quality.

Finalizing the Deal

Once you've chosen the most favorable quote, confirm the order details, payment terms, and warranty provisions. Establishing a clear contract helps prevent misunderstandings down the line.

Conclusion

Securing competitive OEM SS304 braid metal hose quotes demands a thorough understanding of your specific needs and a strategic approach to supplier engagement. By carefully considering all influencing factors and following a structured quotation process, businesses can ensure they obtain the best value for their investment while maintaining the high standards essential for their operations. Remember, the right partnership with an OEM can lead to long-term cost savings, enhanced product performance, and a solid foundation for your business's growth. Latest news

-

Best Four Steel Wire Spiral Hose Hydraulic R12 – Durable High-Pressure Hose Manufacturer

NewsJul.08,2025

-

High-Quality 1/4 Hydraulic Hose – Soft, Flexible & Durable Rubber Hoses for Industrial Use

NewsJul.08,2025

-

1 1 2 Inch Hydraulic Flexible Hose - Durable, Reliable, High-Pressure Solutions

NewsJul.07,2025

-

High-Quality 1 2 Rubber Hose - Durable, Flexible Hydraulic Solutions

NewsJul.07,2025

-

Discover SAE Hydraulic Hose Types - High Quality & Durable Hoses from Leading Factory Supplier

NewsJul.06,2025

-

High Pressure Wire Hydraulic Rubber Hose Supplier Durable & Reliable 1SN Hose Solutions

NewsJul.06,2025