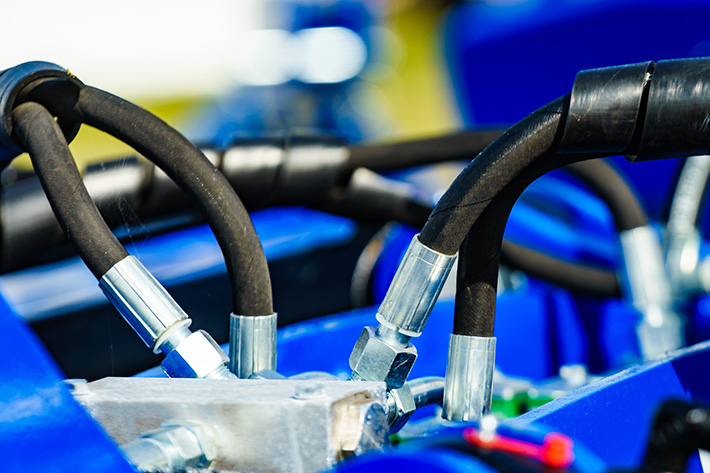

Hydraulic hoses are an integral part of various industrial and mobile applications, transferring hydraulic fluid to power machinery and equipment efficiently. Although hydraulic hoses play a vital role, if not regularly checked, they are prone to failure.

Hydraulic hose failure can potentially lead to expensive downtime, safety concerns, and environmental threats.

Let’s investigate the reasons behind hydraulic hose failures and examine proactive strategies to guarantee peak performance and safety within hydraulic systems.

LOW PRESSURE AIR & WATER RUBBER HOSE

Common Causes of Hydraulic Hose Failure:

1.Abrasion and Wear: One of the leading causes of hydraulic hose failure is abrasion. Hoses operating in harsh environments, such as construction sites or mining operations, often come into contact with abrasive materials or rough surfaces, leading to the gradual deterioration of the hose cover. Over time, this abrasion weakens the hose’s integrity, eventually leading to leaks or bursts.

Prevention: To prevent abrasion-related failures, consider using protective sleeves or guards for hoses, made from materials like nylon or plastic. Routinely inspect hoses for signs of wear and replace them promptly if any damage is detected.

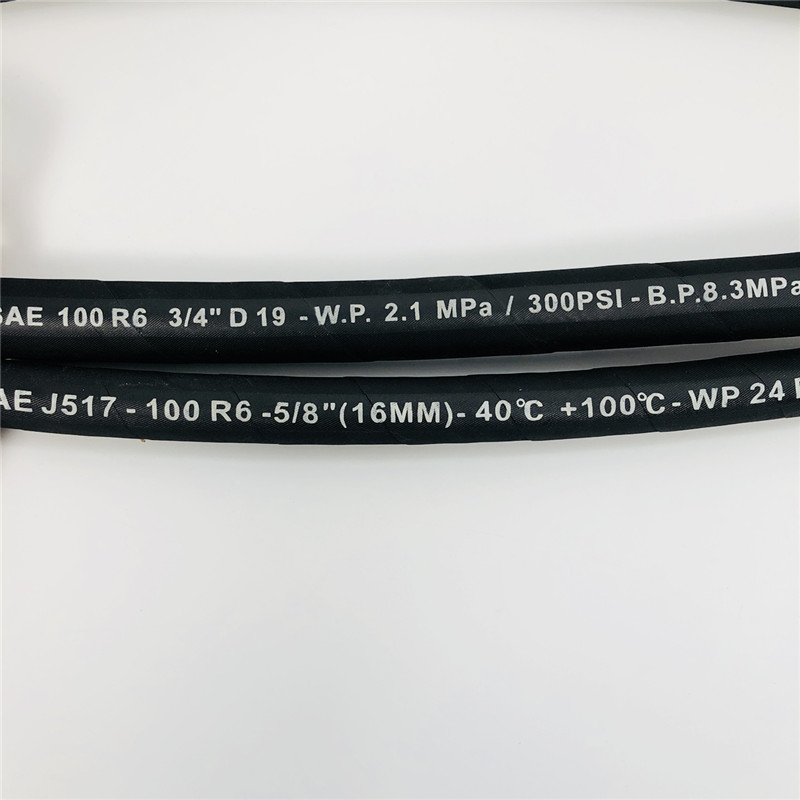

2.Excessive Pressure: Operating hydraulic systems above their recommended pressure limits can cause hoses to fail catastrophically. High pressure can lead to hose ballooning, ruptures, or detachment from their fittings, endangering personnel and equipment.

Prevention: Ensure that the hydraulic system is designed and calibrated to operate within the recommended pressure range. Regularly inspect pressure gauges and relief valves to guarantee proper pressure regulation.

3.Incorrect Assembly and Installation: Improper assembly and installation of hydraulic hoses can lead to leaks and hose blowouts. This includes using the wrong fittings, insufficiently tightening connections, or kinking the hoses during installation.

Prevention: Follow manufacturer guidelines and industry best practices for hose assembly and installation. Use compatible fittings and appropriate torque specifications. Provide adequate support and routing to avoid kinking or bending of hoses.

4.Fluid Compatibility: Selecting the wrong hydraulic fluid or using incompatible fluids can cause chemical reactions that weaken the hose’s inner tube or cover, leading to failure.

Prevention: Always use hydraulic fluids recommended by the equipment manufacturer. Store and handle fluids properly to prevent contamination or mixing of different fluids.

5.Age and Degradation: Hydraulic hoses have a limited service life, and their materials degrade over time due to environmental factors like temperature fluctuations, UV exposure, and chemical exposure.

Prevention: Implement a proactive maintenance program that includes regular inspections and hose replacements based on age, service hours, or manufacturer recommendations.

Preventive Measures for Hydraulic Hose Failure:

1.Regular Inspections: Implement a systematic inspection schedule to check hoses for signs of wear, abrasion, leaks, or any other damage. Early detection can help prevent catastrophic failures and reduce downtime.

2.Training and Education: Ensure that all personnel handling hydraulic systems receive proper training on hose assembly, installation, and maintenance procedures. Knowledgeable employees are better equipped to identify potential issues and address them promptly.

3.Proper Routing and Support: Carefully plan and route hydraulic hoses to avoid sharp bends, kinks, or entanglement with other components. Secure hoses with appropriate clamps and supports to prevent excessive movement and wear.

4.Selecting High-Quality Hoses: Invest in premium-quality hoses designed for specific applications and operating conditions. High-quality hoses are more durable, have better resistance to abrasion and chemicals, and ultimately result in longer service life and reduced failure risks.

In Review

Understanding the common causes of hydraulic hose failure and implementing preventive measures are essential to maintain efficient and safe hydraulic systems. By prioritizing regular inspections, proper installation, fluid compatibility, and training, businesses can significantly reduce downtime, enhance equipment reliability, and safeguard personnel and the environment.