Jun . 20, 2024 15:44 Back to list

Braided Hydraulic Hose VS Spiral Hydraulic Hose

Braided Hydraulic Hose VS Spiral Hydraulic Hose

It is important that you install the right hose type for your hydraulic system to work efficiently. You’ll find rubber, thermoplastic, and Teflon hydraulic hose among the top options in terms of construction.

However, the above refers to the outer layer of the hose. In addition to the inner tube, hydraulic hoses usually come with an outer layer and a reinforcement layer.

Looking closer at the reinforcement layer, there are two primary design types to go with – braided or spiral design. The question is, braided hydraulic hose vs spiral hydraulic hose, which is better?

Read on to learn about them and their best applications. In the end, you’ll be able to choose the right hose for your hydraulic system.

Braided VS Spiral Hydraulic Hose at a Glance

Below is a rundown of the key differences between braided hydraulic hoses and spiral Hydraulic Hoses.

| Braided Hydraulic Hose | Spiral Hydraulic Hose | |

| DESIGN | Braided hydraulic hoses feature a braid-like design with steel wires in an alternating crisscross pattern. | Spiral hydraulic hoses feature a spiral-like design with steel wires in parallel p |

| EASE OF PRODUCTION | Braided hydraulic hoses require heavy machinery to produce. | Spiral hydraulic hoses are relatively easier and faster to manufacture. |

| STRENGTH | Braided hydraulic hoses have a high tensile strength due to interlocking steel wires. | Spiral hydraulic hoses require more spiral steel wires to withstand pressure. |

| APPLICATION | Braided hydraulic hoses work best for high-tensile strength applications. | Spiral hydraulic hoses work best for high-pressure applications. |

| FLEXIBILITY | Braided hydraulic hoses are relatively flexible. | Spiral hydraulic hoses are relatively rigid |

| BENDABILITY | Braided hoses have a tighter bend radius. | Spiral hydraulic hoses are highly resistant to bending. |

| POPULARITY | Braided hydraulic hoses are more common in hydraulic applications than Spiral hoses. | Spiral hydraulic hoses are relatively less common in hydraulic applications than Braided hoses. |

| ADAPTABILITY | Braided hydraulic hoses work in small spaces with tighter bend radiuses. | Spiral hydraulic hoses are not suitable for applications where there are space limitations. |

What is a Braided Hydraulic Hose?

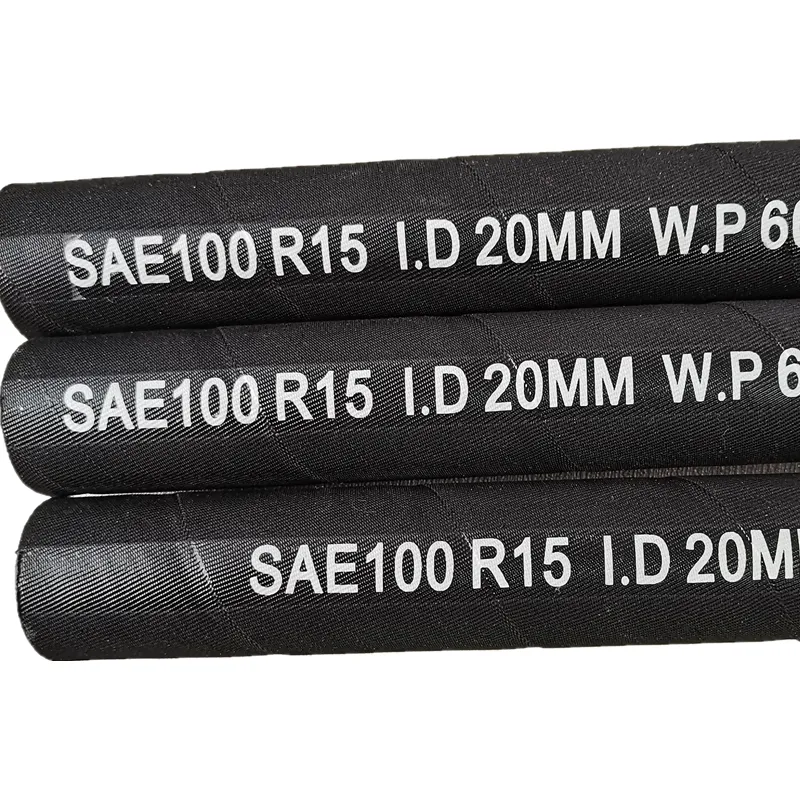

Braided hoses are typically constructed from steel and woven together in a criss-cross formation to form a sturdy framework. Since the braided hydraulic hose has a smaller bend radius, it is more flexible than a standard hydraulic hose.

Notably, the bend radius refers to the minimum diameter a looped hose can reach without getting damaged. As a result, braided hydraulic hoses are a more suitable solution if you are working on a hydraulic system with limited space.

HIGH PRESSURE HYDRAULIC HOSE SAE 100 R12

Braided hydraulic hoses are relatively popular in different markets around the world. This is mainly because they are great for a wide variety of applications. Also, they are usually produced with premium materials, which makes them durable.

While the reinforcement layer features criss-cross steel wires, the outer layer typically features abrasion, weather, and ozone-resistant synthetic rubber material. In addition, most braided hydraulic hoses come with oil-resistant synthetic rubber inner tubes.

They come in different types – single or multiple plies of steel braids for better pressure resistance. For instance, you can have a one-wire braided hose, a two-wire braided hose, and so on.

What is a Spiral Hydraulic Hose?

Spiral hydraulic hoses have reinforcement wires that wrap around the hose in a perpendicular structure. The reinforcement wires maintain a parallel orientation throughout the hose’s length.

Also, the pressure capacity of a spiral hydraulic hose remains constant even if the hose’s inner diameter increases. This directly contrasts with braided hoses, which have a lower pressure capability due to their criss-cross design.

However, note that the inner diameter determines how much pressure a spiral hydraulic hose can withstand. A standard spiral hydraulic hose can reach up to 2300 to 6500 PSI WP. Similarly, they can reach up to 24940 PSI BP.

Spiral hoses have superior longevity as they boast superior strength and resistance to abrasion and damage compared to braided hoses. They are about four times more durable.

While these hoses are known for their rigidness, some manufacturers produce relatively lighter and more flexible options than standard.

Best Application For Braided Hydraulic Hose and Spiral Hydraulic Hose

Braided hydraulic hoses will work for medium to high-pressure applications, depending on the wire bands. They do come with different pressure ratings according to local and internal specifications. In particular, many braided hydraulic hoses either follow the SAE or DIN standards.

However, braided hydraulic hoses fall short when it comes to high-impulse applications. For instance, they are not dependable in jackhammer hydraulic systems, where pressure rapidly increases and drops.

Over time, the braids will become untied due to expansion and contraction in such rapid pressure systems. In addition, due to the friction created by the overlapping wires, the braids can also become hot. It increases the possibility of failure and shortens the hose’s lifespan in the long run.

On the other hand, spiral hydraulic hoses are well-suited for high-impulse environments due to their rigidness. As a result, they are common with heavy-duty hydraulic systems.

Since they are not very flexible compared to braided hydraulic hoses, they can withstand higher pressures. Their durable construction ensures they work well even in subfreezing temperatures.

Spiral hydraulic hoses can typically operate from -40 to 100 degrees Celsius, with diameters ranging from 3/4 to 2 inches on the inside.

You can tell if a spiral hose is suitable for your task and application by considering the pressure, abrasion, and vibration levels of your hydraulic system. They are usually the go-to options for systems that don’t need an overly tight bend radius.

The Importance of Choosing the Right Hose Type

One hydraulic hose won’t work in all applications, so it’s necessary to choose carefully. Most people usually consider the fluid and chemicals the hose come in contact with, which is commendable.

However, they aren’t the only variables you should consider. Especially when it comes to choosing between a braided hydraulic hose and a spiral hydraulic hose.

In such an instance, the hydraulic hose pressure rating is vital. Diameter and pump volume determine a hose’s pressure resistance. If your hydraulic system requires a high-pressure hose, you should opt for a spiral hydraulic hose.

Next, consider if the hose needs to be bent, folded, and unfolded during operation. If it does, what’s significant is the bend radius. In this case, a braided hydraulic hose is suitable for such applications.

It’s perfectly normal to consider price when choosing the right hose type. However, you shouldn’t save money by getting an unreliable hose – whether spiral or braided – as you’ll be risking damage to your hydraulic system.

-

Steel Spiral Wire Hydraulic Hose in China - Reliable Supplier & Competitive Prices

NewsJun.10,2025

-

1/4 Inch Hydraulic Hose Supplier - High Quality OEM 3/8 Inch Hydraulic Hose Manufacturers & Service

NewsJun.10,2025

-

1/2 Inch Hydraulic Hose Bulk - Durable, Flexible Bulk Hydraulic Hoses for Industrial Use

NewsJun.10,2025

-

Premium OEM Automotive Hose Supplier & Exporter Durable Solutions

NewsJun.10,2025

-

China PTFE Teflon Hose Exporters High-Temp & Chemical-Resistant

NewsJun.10,2025

-

Premium Hydraulic Suction Hose Flexible & Durable for Industrial Use

NewsJun.10,2025